Carbon fibers with less fluff and excellent processability are obtained, contributing to the production of high-strength and highly reliable (Carbon Fiber Reinforced Polymer) CFRP.

What’s great about “CHEMITYLEN”

Carbon fibers with less fluff and excellent processability are obtained, contributing to the production of high-strength and highly reliable (Carbon Fiber Reinforced Polymer) CFRP.

What’s great about “CHEMITYLEN”

High-quality carbon fibers with excellent handling and processability are obtained by using “CHEMITYLEN”

*Fiber opening property: A property that enables thin and uniform spreading of carbon fibers in the fiber opening process, in which carbon fiber bundles are unraveled to spread carbon fibers in order to facilitate impregnation of the matrix resin.

We have a diverse lineup of products for various applications.

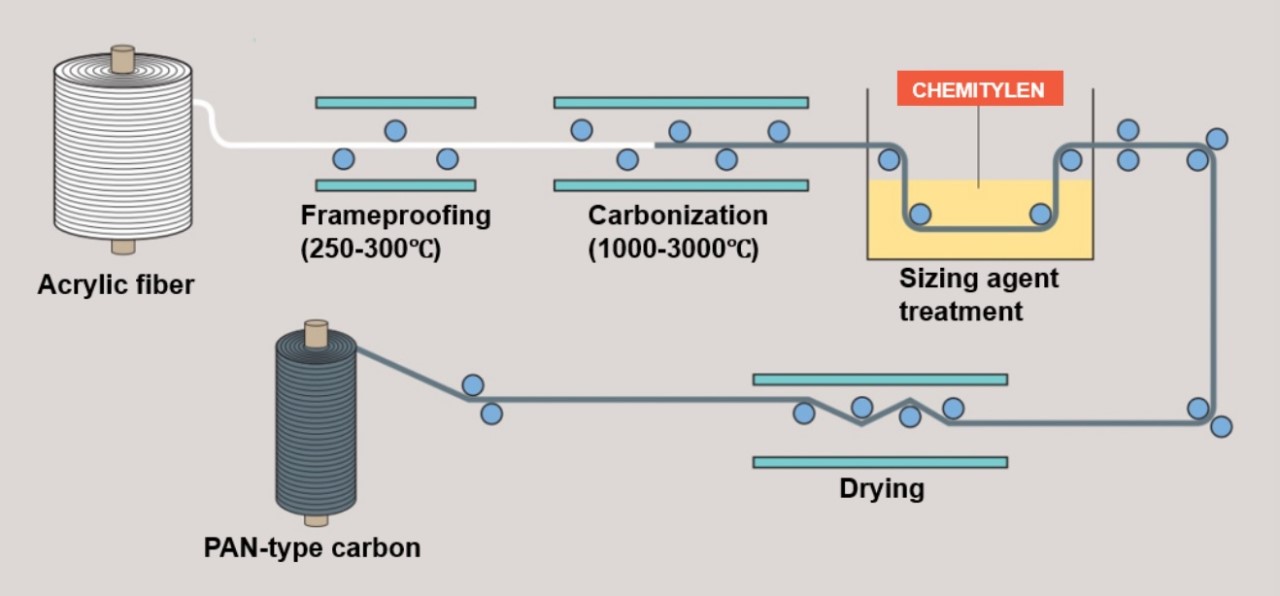

“CHEMITYLEN” products are sizing agents that bind carbon fibers together for easier handling.

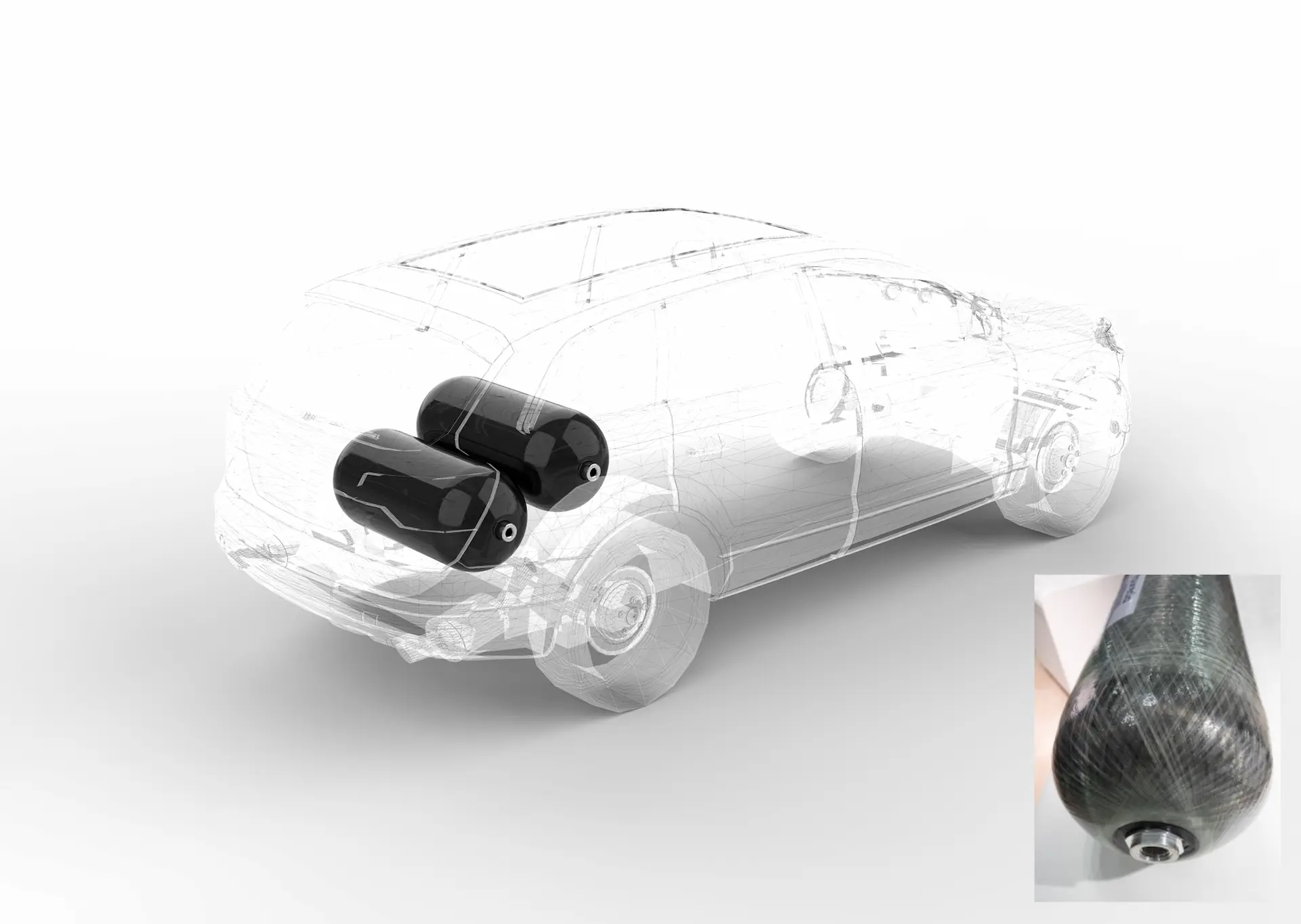

Carbon fiber composite materials can achieve both high strength and lightweight, contributing to energy saving and reduction of environmental impact in various fields.

Molded by filament winding using sized carbon fibers.

Molded by pull-torsion using sized carbon fibers.

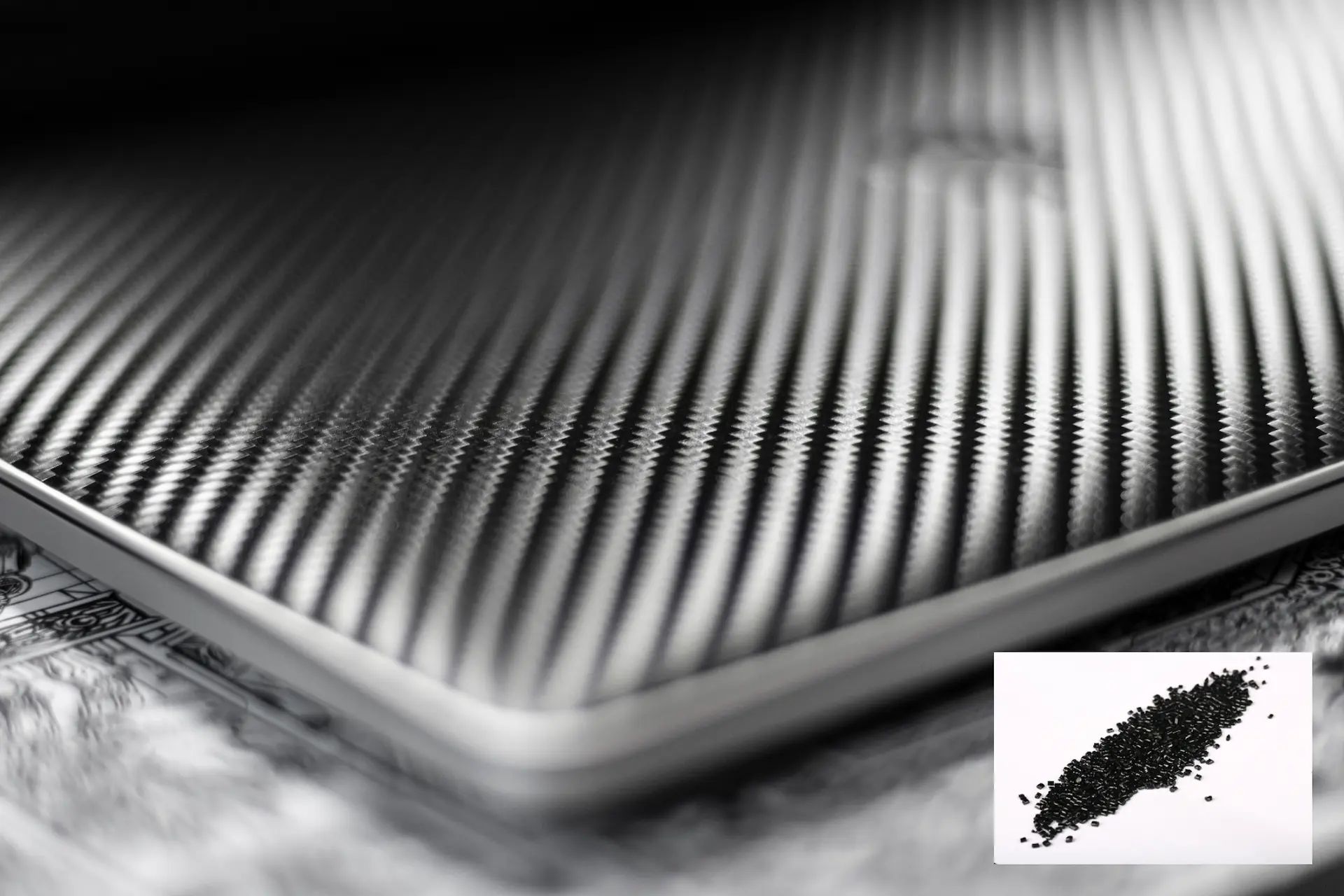

Sized carbon fibers are used as prepreg and press molded.

Sized carbon fibers are used as prepreg and autoclave molded.

Sized carbon fibers are woven and molded by RTM process (cured after pre-molding)

Sized carbon fibers are pelletized as chop fiber and then injection molded.

| Products | Features | Effects |

| CHEMITYLEN HP・EP (Polyester/Epoxy type) | Excellent impregnation of epoxy resin. | Wets well with epoxy resin and produces high-strength FRP. |

| Excellent fiber-opening properties. | Produces a wide, thin tow. | |

| Less fluffing. | Fiber length can be maintained and high-strength FRP can be made. | |

| CHEMITYLEN UA (Polyurethane type) | Excellent flexibility and cuttability. | Produces flexible, easy-to-handle, easy-to-chop tow. |

| Excellent mixing stability with EP and HP series. | The physical properties can be adjusted to your liking by mixing. | |

| CHEMITYLEN WS (Polyether type) | Good dispersibility in water. | When you do not want to leave the sizing agent component on the surface of carbon fiber, it can be washed off with water. |

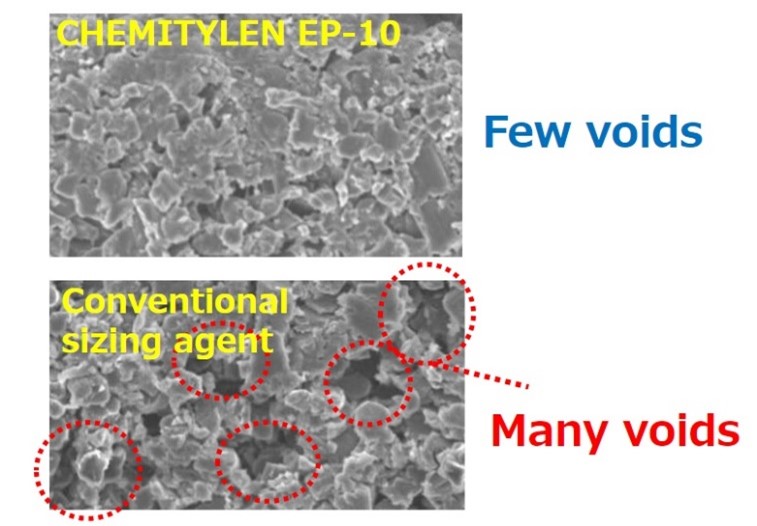

Fig. Carbon fiber composite material after epoxy resin impregnation SEM photograph of cross-section (800x)

| Item | Conventional sizing agents (Main component: epoxy resin) | CHEMITYLEN EP-10 | CHEMITYLEN HP-10 | |

| Adhesion amount wt% | 1.5 | 1.5 | 1.5 | |

| Carbon fiber tow basic performance | Fluff amount (mg) | 2.9 | 0.7 | 0.5 |

| Convergence (cm) | 13.4 | 18.6 | 17.1 | |

| Openness (mm) | 6.5 | 6.7 | 7.4 | |

| Epoxy resins aggregation (s) | 18.5 | 6.9 | 5.7 | |

| Emulsion stability | Stability over time 25℃×6months | Fair | Good | Good |

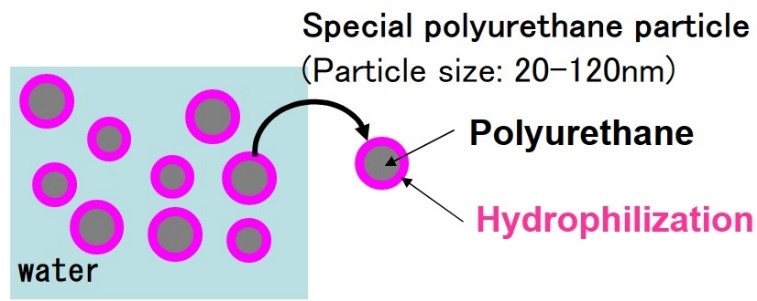

Fig. CHEMITYLEN UA products

| Item | Conventional sizing agent (Main component: epoxy resin) | CHEMITYLEN UA-40 |

| Adhesion amount wt% | 1.5 | 1 |

| Convergence cm | 13.4 | 18.3 |

| Cuttability |  |  |

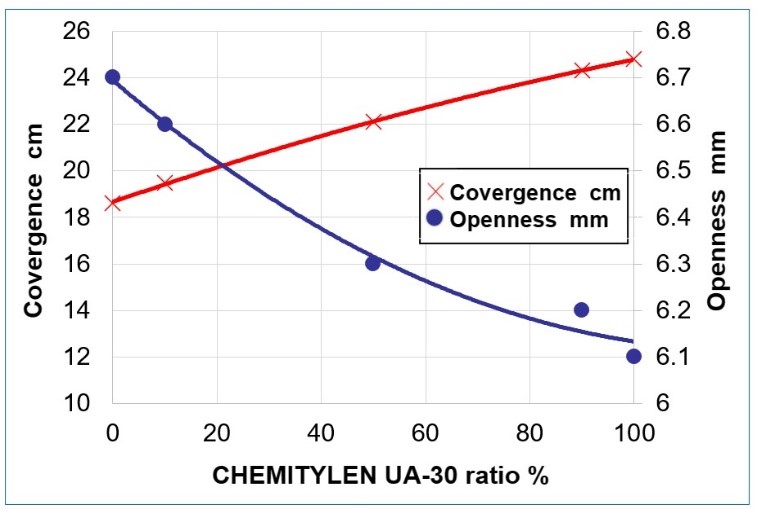

Example of performance adjustment by mixing Chemtylen EP-10/UA-30

A water-soluble type carbon fiber sizing agent with excellent solubility in water.

| Item | CHEMITYLEN WS-10 | CHEMITYLEN WS-20 |

| Main composition | Polyether aqueous solution | Modified polyether aqueous solution |

| Concentration | 50 | 30 |

| Viscosity (25°C, mPa-s) | 3000 | 25000 |

| Item | Conventional sizing agent (Main component: epoxy resin) | CHEMITYLEN WS-10 | CHEMITYLEN WS-20 |

| Adhesion amount wt% | 1.5 | 1.5 | 1.5 |

| Convergence cm | 13.4 | 13.1 | 23.8 |

| Openness mm | 6.5 | 6.6 | 6.4 |

| Product | Carbon fiber tow performance | Heat resitance | |||

| convergence | tack | densitometry | fluff | Tg ℃* | |

| CHEMITYLEN HP-10 | normal | midldle | excellent | excellent | 300 |

| CHEMITYLEN EP-10 | good | midldle | excellent | good | 310 |

| CHEMITYLEN UA-10 | excellent | weak | normal | excellent | 270 |

| CHEMITYLEN UA-20 | excellent | weak | good | excellent | 250 |

| CHEMITYLEN UA-30 | good | weak | good | good | 270 |

| CHEMITYLEN UA-40 | good | weak | excellent | good | 230 |

| CHEMITYLEN WS-10 | poor | strong | good | N/A | 220 |

| CHEMITYLEN WS-20 | good | midldle | good | N/A | 310 |

*Temperature at 5% thermal loss during heating of pure resin (in N2, temperature increase at 10°C/min)

| Product | Liquid type | Concentration % * | Resin type | Ionic species |

| CHEMITYLEN HP-10 | emulsion | 40 | modified polyester | nonion |

| CHEMITYLEN EP-10 | emulsion | 40 | modified polyester | nonion |

| CHEMITYLEN UA-10 | emulsion | 39 | modified polyurethane | anion |

| CHEMITYLEN UA-20 | emulsion | 38 | modified polyurethane | anion |

| CHEMITYLEN UA-30 | emulsion | 40 | modified polyurethane | anion |

| CHEMITYLEN UA-40 | emulsion | 35 | modified polyurethane | anion |

| CHEMITYLEN WS-10 | aqueous solution | 50 | polyether | ー |

| CHEMITYLEN WS-20 | aqueous solution | 50 | modified polyether | ー |