SANHIBITOR products are organic rust inhibitors which prevent the generation of rust by forming lubricating films on metal surfaces, and are classified into two types, the water-soluble type (including water dispersible type) and the oil-soluble type. Water-soluble type products can be used for rust prevention of metal surfaces following dilution with water, or for corrosion inhibition of metal parts through their addition in coolant, metal working fluid, etc. Oil-soluble type products are generally added to lubricating oil (engine oil, turbine oil, lubricating oil for sliding surfaces, hydraulic oil, gear oil, etc.), fuel oil (gasoline, gas oil, etc.) or metal working oil (cutting oil, drawing oil, rolling oil, press forming oil, etc.) as rust inhibitors for metal parts.

SANHIBITOR: Rust Inhibitors for Various Metals

Features of SANHIBITOR

We offer the following range of SANHIBITOR products:

| Product name | Type | Metal to which Rust Preventive Properties are Impacted | |||||

|---|---|---|---|---|---|---|---|

| Water soluble | Oil soluble | Iron | Copper | Brass | Aluminum | Zinc Alloy | |

| SANHIBITOR No.50 | x | x | |||||

| SANHIBITOR 150 | x | x | x | ||||

Value of symbols “x”: Fulfilled (annotation: Even SANHIBITOR products that are NOT marked with a “x”, exhibit some rust preventive properties

SANHIBITOR No.50 has the following features:

- Produces less foam

- Soluble even in mineral oil of aniline point under 70, and also in acid water

SANHIBITOR 150 has the following features:

- Exhibits excellent rust preventive property when used in small amounts.

- Has good solubility with lubricating oil such as turbine oil.

- Has low viscosity and easy to handle.

- Excels in demulsibility.

Typical properties of SANHIBITOR products

| Product name | Appearance at 20C | Color (Gardner) | pH * | Acid Value(KOH Method) | Specific Gravity 15C/4C | Kinematic viscosity mm2/s(40C) |

|---|---|---|---|---|---|---|

| SANHIBITOR No.50 | Colorless liquid | 7 | 11.0 | - | 1.036 | 144 |

| SANHIBITOR 150 | Pale straw-colored liquid | <1 | - | 159 | 0.965 | 1.250 |

*1wt% aqueous solution

Typical Applications of the water-soluble rust inhibitor

1. Rustproofing of ferrous metal parts

Soak in the following rust inhibitor water dilution bath(*) for 20 to 120 seconds, then air dry.

(*) SANHIBITOR No.50: 0.50 – 1.0wt% aqueous solution (bath temperature: 20 – 80⁰C)

2. Rust prevention for metals in contact with water, such as cooling water piping

The following rust inhibitor is blended in water.

SANHIBITOR No.50: 0.5wt%

3. Preparation of water-soluble metalworking fluids

(cutting oil, rolling oil, forging oil, etc.)

The following rust inhibitor is blended in metalworking fluids.

SANHIBITOR No.50: 5 -10wt% *

(*0.05 -0.5% after dilution)

Typical Applications of the oil-soluble rust inhibitor

1. Rustproofing of ferrous metal parts

Soak in the following rust inhibitor mineral oil solution bath(*) for 20 to 120 seconds, then remove liquid.

(*) SANHIBITOR 150: 1-5wt% mineral oil (bath temperature: 20 – 80⁰C)

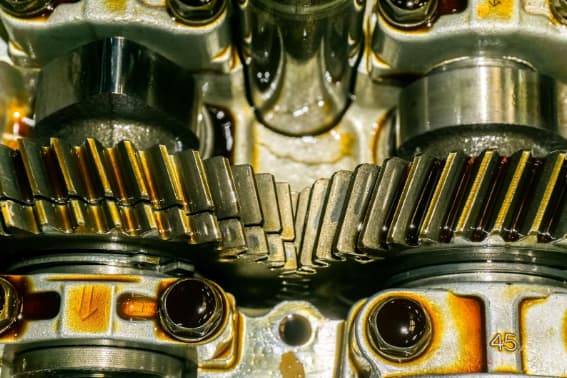

2. Preparation of lubricants

(turbine oil, sliding surface oil, hydraulic oil, gear oil, etc.)

The following rust inhibitor is blended in lubricants.

SANHIBITOR 150: 0.2-1.0wt%