Pelectron is a polymer-type antistatic agent.

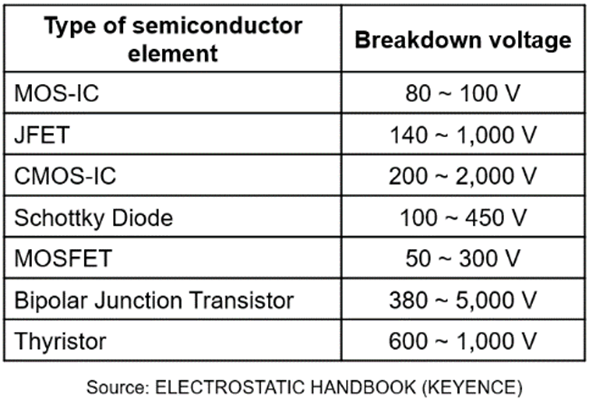

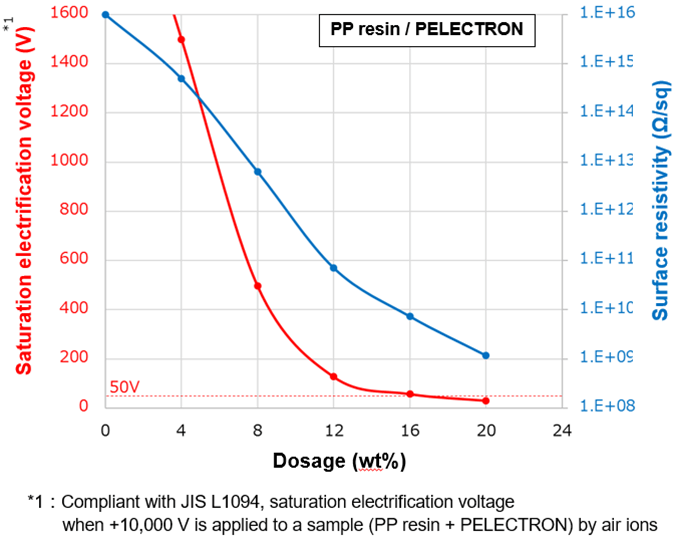

- Electrification voltage can be flexibly controlled (<50V or less)

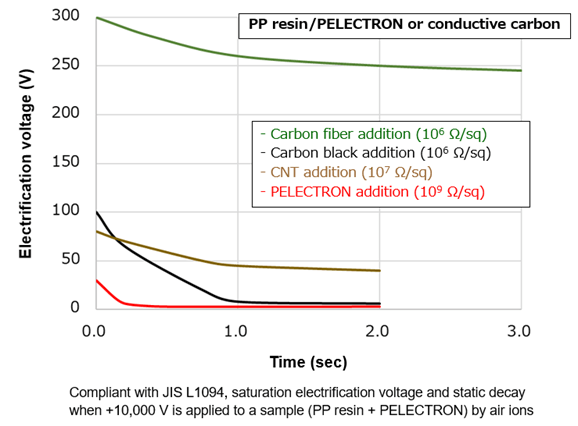

- Low electrification voltage and rapid charge decay

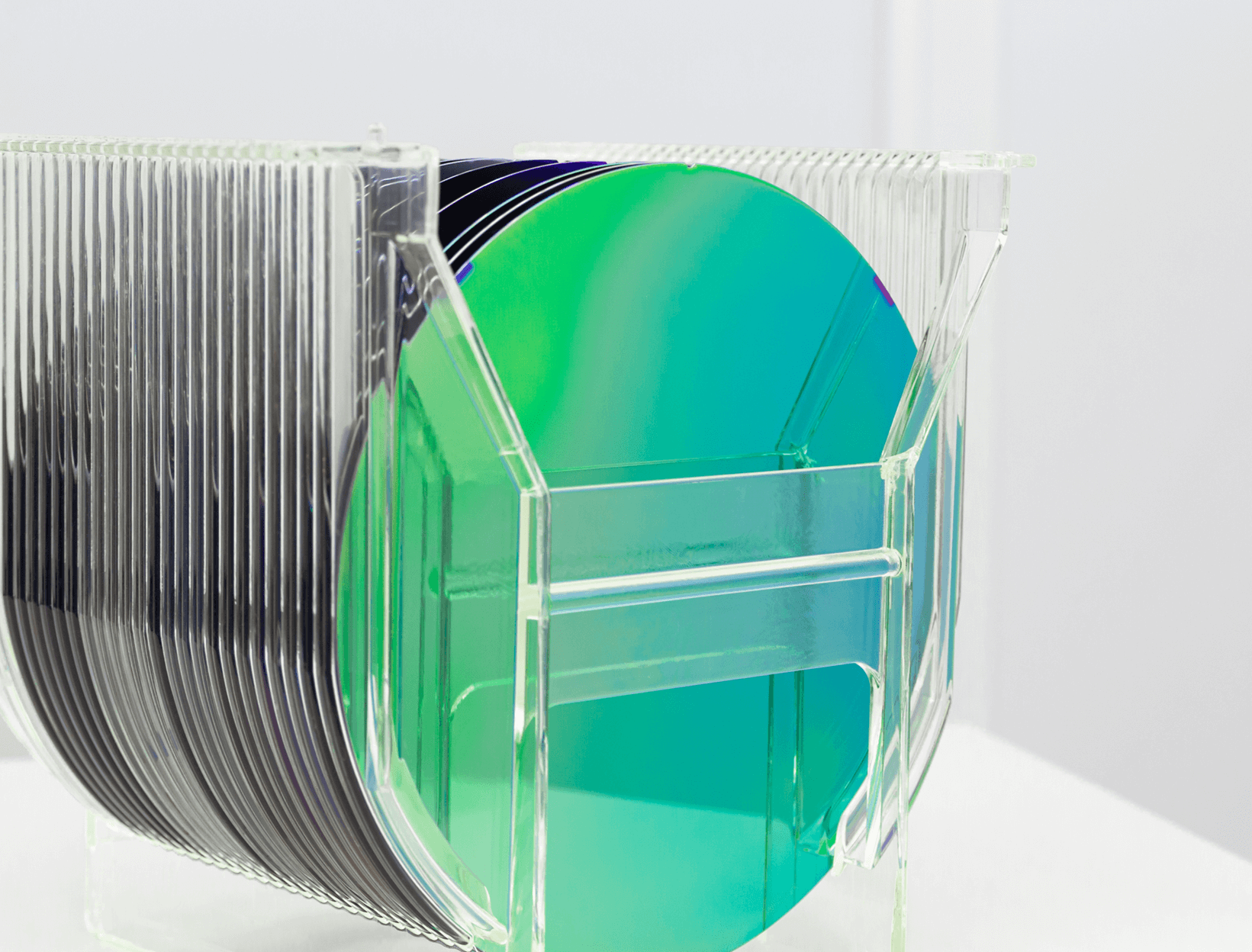

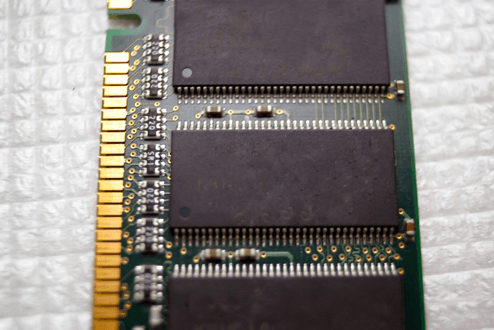

- Low dust emission makes it ideal for static control in clean application

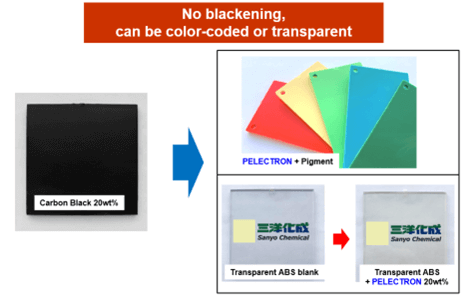

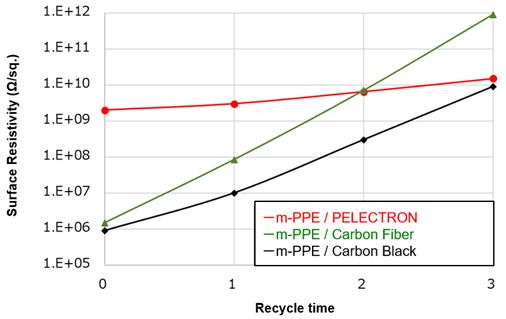

- More recyclable than conductive carbon

- No black color, can be color-coded or transparent