FUNCTIVE Additive for ABS and PC/ABS Blends

Enhanced Chemical Resistance at Low Addition Levels

Minimal Effect on Mechanical Properties

ABS and PC/ABS offer substantial performance advantages including thermoformability, dimensional stability (resistance to warpage) and impact resistance. However, these materials suffer from poor chemical resistance which affects mechanical properties and clarity for transparent grades. Fortunately, FUNCTIVE was developed to improve the chemical resistance while maintaining other properties. A summary is presented on this page. For more detail, request the whitepaper. Samples are also available.

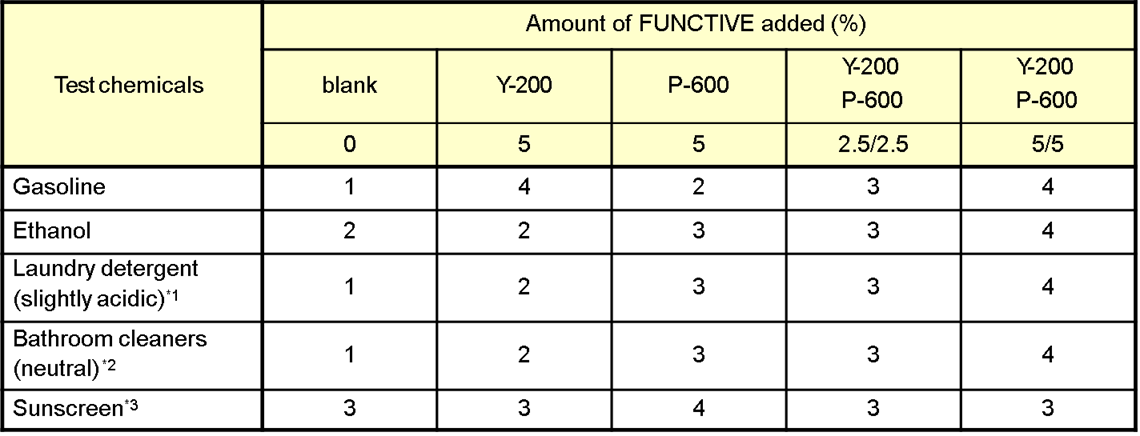

FUNCTIVE Improves the Chemical Resistance of ABS

Test method:

The injection-molded test piece was fixed on the ¼-oval test piece described on page 8 and 9, and chemicals were applied to it. The samples were left for 20 hours under the condition of 23°C and 50RH%, and the critical strain value (ε) was calculated from the crack occurrence position.

- Critical strain value 1: Poor chemical resistance (ε<0.7)

- Critical strain value 2: Average chemical resistance (0.7≦ε<0.8)

- Critical strain value 3: Good chemical resistance (0.8≦ε)

- Critical strain value 4: Excellent chemical resistance (No cracks)

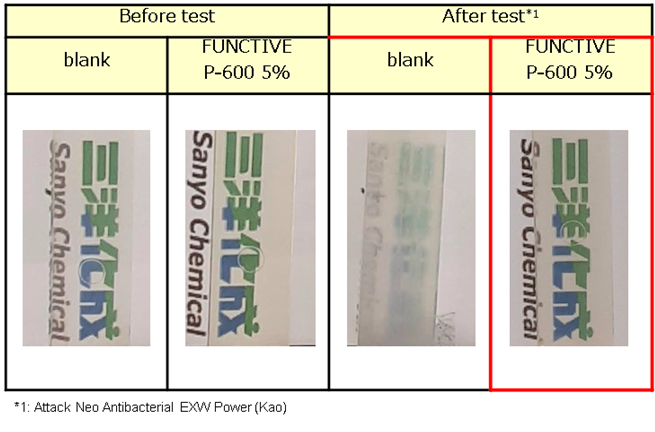

*1: Attack Neo Antibacterial EXW Power (Kao)

*2: Bathmagiclean (Kao)

*3: Neutrogena(SPF55)

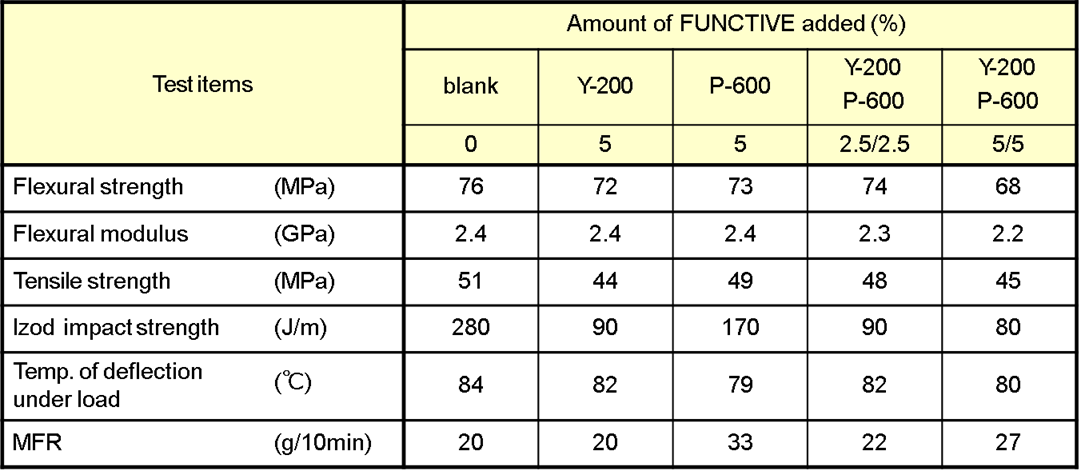

FUNCTIVE has Minimal Effect on the Mechanical Properties of ABS

Materials:

According to the above table, each of the compounds was kneaded using a single screw extruder at 250oC, and then molded using an injection molding machine (nozzle temp.: 250oC, mold temp.:50oC).

ABS resin and FUNCTIVE were dried at 80oC for 3hours.

ABS resin: general purpose injection-molded type[MVR=18 cm3/10min(220oC, 98N)]

Test method:

Flexural test: ASTM D790, Tensile test: ASTM D638, Izod impact strength: ASTM D256 (with notch)

Temp. of deflection under load: ISO 75(1.80MPa), MFR: ASTM D1238 (220oC, 10kgf)

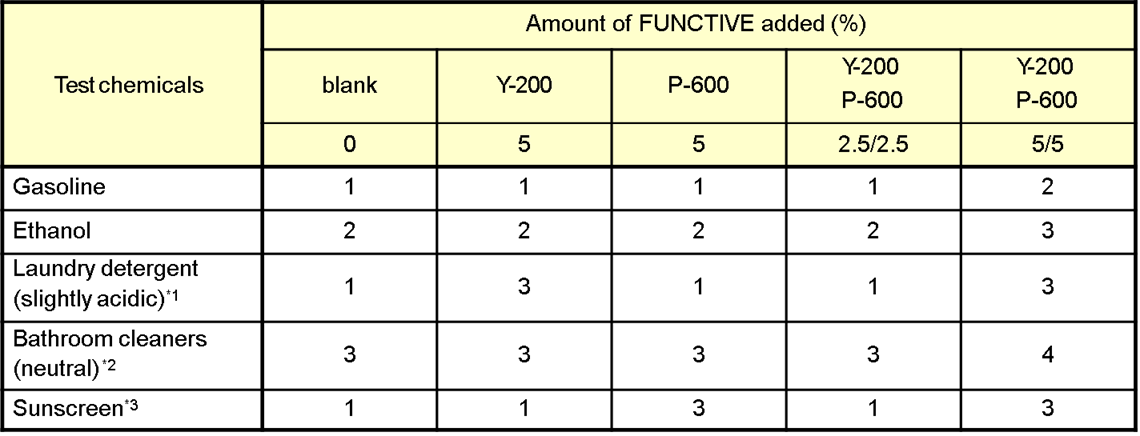

FUNCTIVE Improves the Chemical Resistance of PC/ABS Blends

Test method:

The injection-molded test piece was fixed on the ¼-oval test piece described on page 8 and 9, and chemicals were applied to it. The samples were left for 20 hours under the condition of 23°C and 50RH%, and the critical strain value (ε) was calculated from the crack occurrence position.

- Critical strain value 1: Poor chemical resistance (ε<0.7)

- Critical strain value 2: Average chemical resistance (0.7≦ε<0.8)

- Critical strain value 3: Good chemical resistance (0.8≦ε)

- Critical strain value 4: Excellent chemical resistance (No cracks)

*1: Attack Neo Antibacterial EXW Power (Kao)

*2: Bathmagiclean (Kao)

*3: Neutrogena(SPF55)

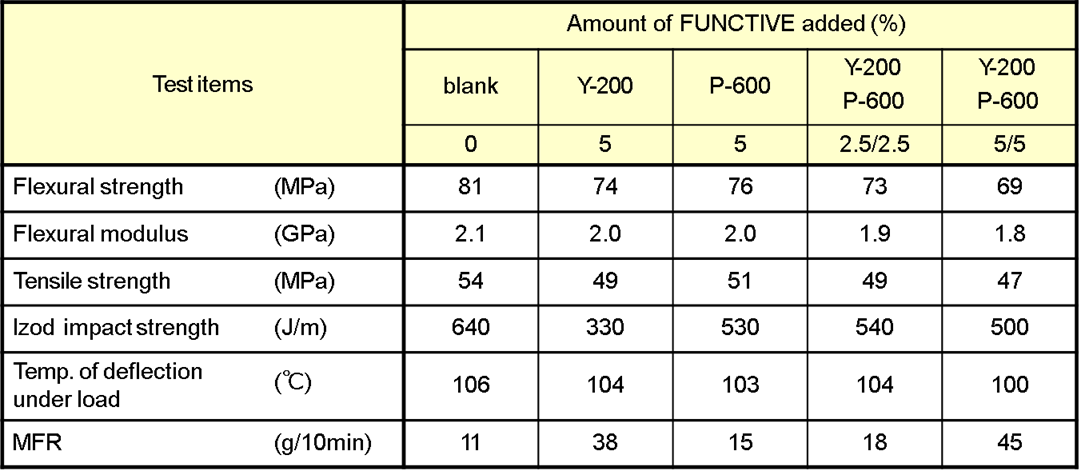

FUNCTIVE has Minimal Effect on the Properties of PC/ABS Blends

Materials:

According to the above table, each of the compounds was kneaded using a single screw extruder at 250oC, and then molded using an injection molding machine (nozzle temp.: 250oC, mold temp.:90oC).

PC/ABS alloy and FUNCTIVE were dried at 100oC for 4hours and 80oC for 3hours respectively.

PC/ABS alloy:MFR=29 g/10min(240oC, 98N)

Test method:

Flexural test: ASTM D790, Tensile test: ASTM D638, Izod impact strength: ASTM D256 (with notch)

Temp. of deflection under load: ISO 75(1.80MPa), MFR: ASTM D1238 (220oC, 10kgf)

FUNCTIVE Protects the Clarity of Transparent ABS

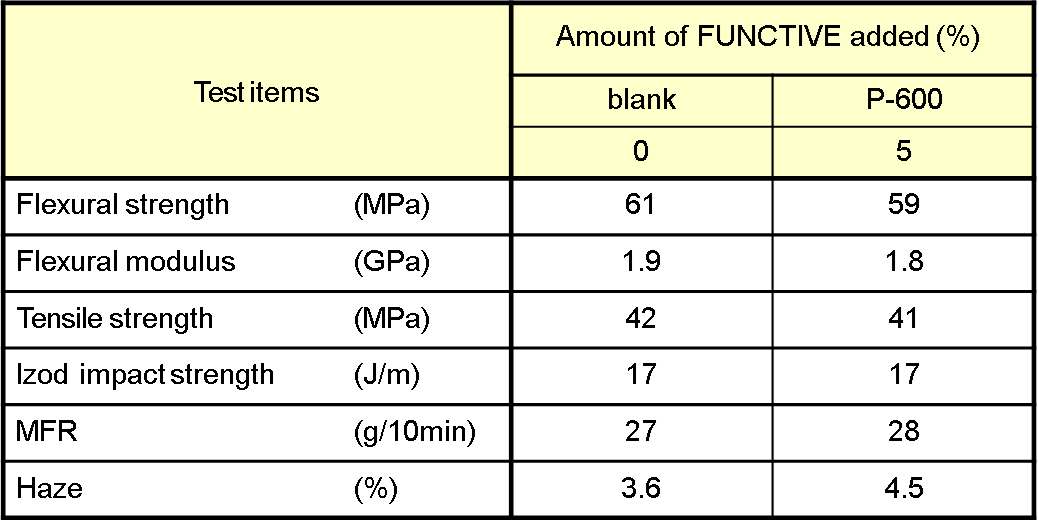

FUNCTIVE has Minimal Effect on the Properties of Transparent ABS

Materials:

According to the above table, each of the compounds was kneaded using a single screw extruder at 250oC, and then

molded using an injection molding machine (nozzle temp.: 250oC, mold temp.:50oC).

ABS resin and FUNCTIVE were dried at 80oC for 3hours.

Transparent ABS resin: General purpose grade [MFR=25 g/10min(220oC, 98N)]

Test method:

Flexural test: ASTM D790, Tensile test: ASTM D638, Izod impact strength: ASTM D256 (with notch)

MFR: ASTM D1238 (220oC, 10kgf), Haze: ISO 14782 (2mmt)