Poly alkylene glycol-based lubricant that combines water solubility, biodegradability, and lubricity.

Poly alkylene glycol-based lubricant that combines water solubility, biodegradability, and lubricity.

EXCEBIOL” is biodegradable and can be used as a lubricant base in various fields to reduce environmental impact in case of accidental leakage.

Lubricant base for wind turbine generators, etc.

Lubricant base for power sources such as marine screws, etc.

Lubricant base for agricultural and construction machinery, etc.

Mold release agents, etc., in the molding and processing field

EXCEBIOL has superior water solubility and biodegradability compared to existing base oils such as ester, mineral, and PAO base oils and exhibits comparable lubricating properties.

Table 1. Main properties of the EXCEBIOL series and comparison with other base oils (1)

| Water-solubility ✓: Homogeneous dissolution (no mark: Insoluble separation) |

Biodegradability [OECD301] ✓: ≧60% |

Lubricity (coefficient) [SRV method]* μ (100N) |

|

|---|---|---|---|

| EXCEBIOL MR-260 |

✓ | ✓ | 0.116 |

| EXCEBIOL MR-660 |

✓ | ✓ | 0.116 |

| EXCEBIOL TE-600 |

✓ | ✓ | 0.153 |

| EXCEBIOL DE-300 |

✓ | ✓ | 0.156 |

| EXCEBIOL DE-1000 |

✓ | ✓ | 0.147 |

| Ester oil | ✓ | 0.137 | |

| Mineral oil | 0.18 | ||

| PAO oil | 0.23 |

*Test conditions for lubricity [SRV method] / Lubricity (coefficient of friction) evaluation using an oscillating friction and wear test (SRV tester)

-Test specimen: Steel ball (SUJ-2, Φ 10 mm), steel disk (SUJ-2)

-Test conditions: Load 100 N (50 → 500 N), frequency 50 Hz, vibration width 1.0 mm, temperature 40°C

Table 2. Main properties of the EXCEBIOL series and comparison with other base oils (2)

| 40°C Kinematic Viscosity (mm2/s) |

100°C Kinematic Viscosity (mm2/s) |

Pour Point (°C) |

|

|---|---|---|---|

| EXCEBIOL >MR-260 |

49 | 11 | -40 |

| EXCEBIOL MR-660 |

141 | 26 | -34 |

| EXCEBIOL TE-600 |

91 | 12 | -61 |

| EXCEBIOL DE-300 |

34 | 6 | -13 |

| EXCEBIOL DE-1000 |

- | 17 | 37 |

| Ester oil | 69 | 8 | -40 |

| Mineral oil | 37 | 7 | -13 |

| PAO oil | 30 | 6 | -61 |

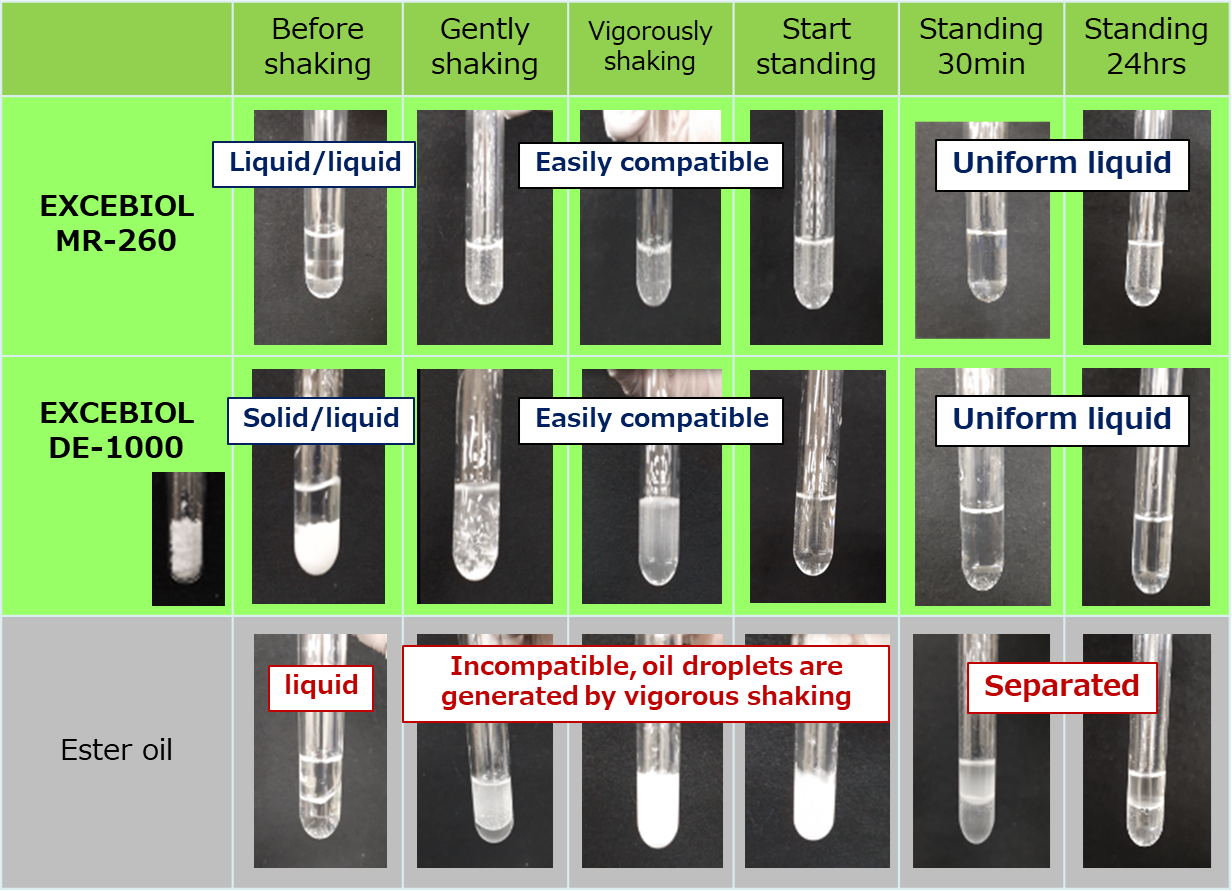

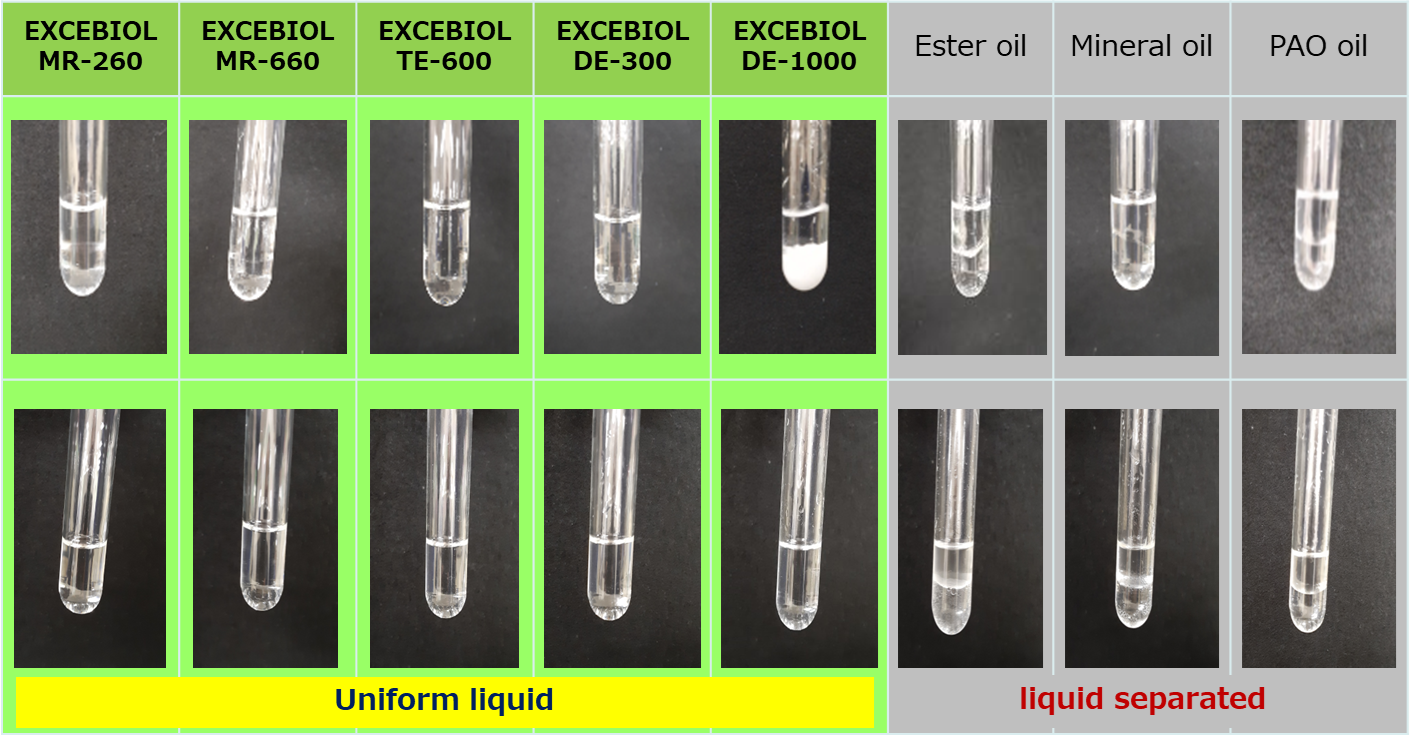

“EXCEBIOL” easily mixes with water and maintains a homogeneous state after shaking.

Table 3. Evaluation of water solubility of “EXCEBIOL”

EXCEBIOL water solubility evaluation test:

[The photographs in the table above show the appearance before shaking and after 24 hours of standing.]

Comparison test:

Ester/mineral oil/PAO base oil was tested similarly, and liquid separation from the water was observed over time.

Table 4. Change in appearance during water solubilization of “EXCEBIOL”