Cold Flow Improver for biodiesel fuel “NEOPROVER”

What Makes Methacrylate Copolymer, “NEOPROVER” Great as a Cold Flow Improver for Biodiesel:

1. Reduced fuel cold filter plugging point (CFPP):

“NEOPROVER” shows excellent low-temperature flowability enhancement performance for biodiesel fuels and is effective in lowering the Cold Filter Plugging Point (CFPP) of biodiesel fuels.

Figure: Effect of adding “NEOPROVER” to FAME-type biodiesel fuel to improve low-temperature flowability

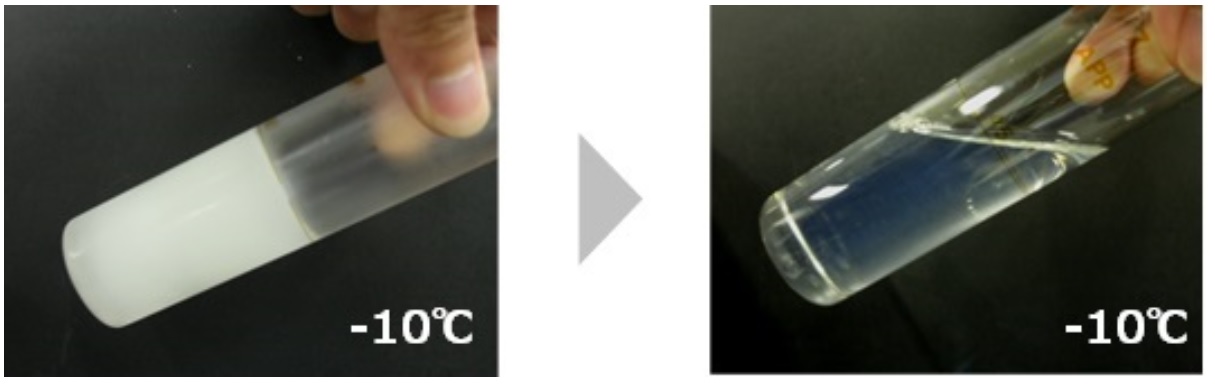

2. Low Pour Point:

“NEOPROVER” itself exhibits great low-temperature fluidity.

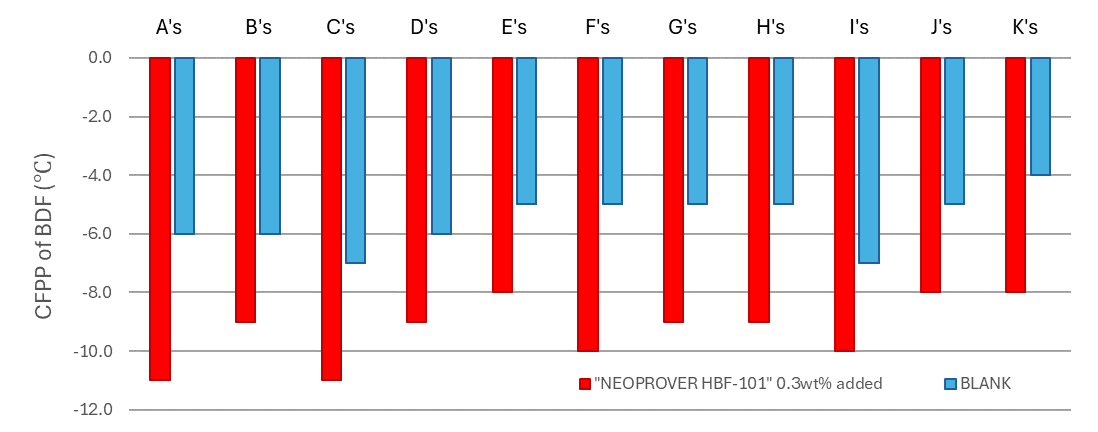

3. Compatible with various biodiesel fuels:

“NEOPROVER” is effective on a wide variety of FAME-type biodiesel fuels.

For example, it has been tested on biodiesel sources such as soy, palm, coconut, and Used Cooking Oil (UCO).

What is FAME-type Biodiesel Fuel (BDF)

Fatty Acid Methyl Ester (FAME) type Biodiesel Fuel (BDF), is a renewable alternative to traditional diesel made by transesterifying vegetable oils or animal fats with methanol. This process produces fatty acid methyl esters (FAME) and glycerin as a byproduct. FAME-type BDF can be used in diesel engines with little to no modification and helps reduce greenhouse gas emissions compared to fossil diesel.

Like fossil fuels, biodiesel fuel emits CO2 during combustion, but the CO2 emitted during use is offset by the CO2 absorbed during the growth of the plants used as raw materials, resulting in zero CO2 emissions in total, making it a carbon-neutral fuel.

Challenges when using FAME-type biodiesel fuel at low temperatures

FAME-type biodiesel fuel has a higher flow point than diesel fuel and tends to have inferior low-temperature flowability. Therefore, when used in cold climates, fuel flowability may deteriorate, causing plugging of filters and pumps, and low-temperature flowability needs to be improved.

Reduction of cold filter plugging point (CFPP) by low-temperature flow improver for biodiesel fuel “NEOPROVER”

The Cold Filter Plugging Point (CFPP) is an index that evaluates the fluidity and freezing point of fuel.

Adding “NEOPROVER” to biodiesel fuel has the effect of lowering the plugging point of the fuel by 2~4℃, contributing to the use of biodiesel fuel in cold climates.

Test Conditions

CFPP: In accordance with JIS K 2289.

Effect of adding “NEOPROVER HBF-101″ to domestic biodiesel fuel (BDF)

“NEOPROVER” works well with a variety of biodiesel fuels.

Figure: Effect of adding “NEOPROVER” HBF-101 to domestic biodiesel fuel (BDF)

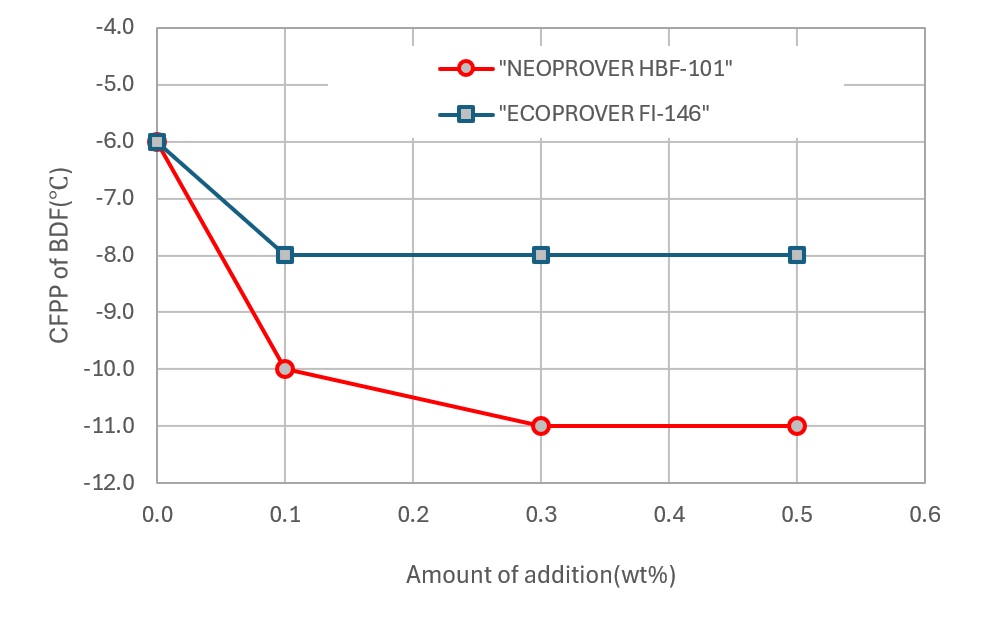

Effect of adding to Company A’s biodiesel fuel (BDF)

“NEOPROVER” is superior to conventional products in reducing the cold filter plugging point of biodiesel fuel.

Figure: Amount added and cold filter plugging point (CFPP) of biodiesel Fuel (BDF)

[Comparison with our conventional products]

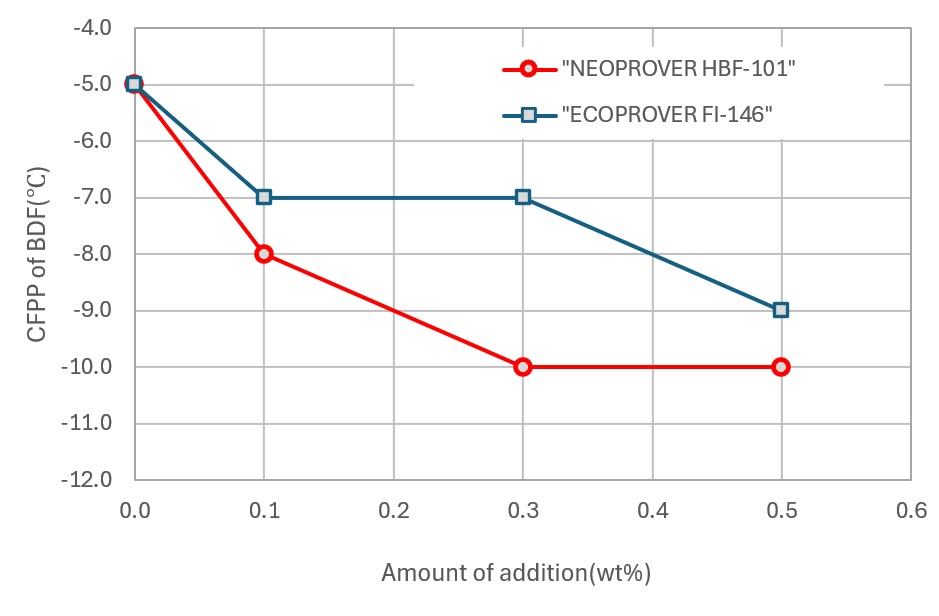

Effect of adding to Company F’s biodiesel fuel (BDF)

Figure: Amount added and cold filter plugging point (CFPP) of biodiesel fuel (BDF)

[Comparison with our conventional products]

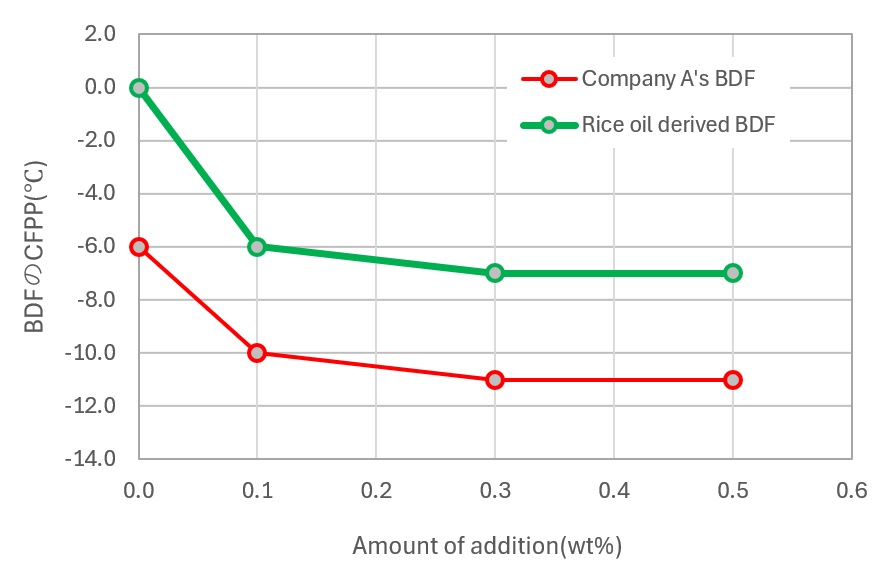

Effect of adding different feedstock types to biodiesel fuel (BDF)

The plugging point reduction effect is also demonstrated for biodiesel fuel made from used cooking oil (rice oil). Therefore, even if the rice oil blending ratio is high, the plugging point reduction effect can be achieved.

Figure: Amount added and cold filter plugging point (CFPP) of Biodiesel Fuel (BDF)

Main properties of low-temperature flow improver for biodiesel fuel “NEOPROVER”

Table: Main properties of NEOPROVER

| Characteristics | Remarks | |

|---|---|---|

| Appearance | Pale yellow to yellow liquid | N/A |

| Number of ASTM color | L0.5 | JIS K 2590 |

| Density | 0.91 g/cm³ | 15℃、JIS K 2249 |

| Kinematic viscosity | 165 mm²/s | 100℃、JIS K 2283 |

| Flow point | -15.0℃ | JIS K 2269 |

Typical values are shown.

Questions Asked About NEOPROVER and Other FAQs

A: NEOPROVER is designed to work with Biodiesel (FAME). It enhances the flowability of BDF in cold weather as a Cold Flow Improver.

A: A Cold Flow Improver (CFI) is an additive used in biodiesel and other fuels to enhance flowability at low temperatures. CFIs are also known as cold flow modifiers, winterizing agents, anti-gel additives, and low-temperature flow enhancers. They are essential for maintaining optimal fuel performance and reliability in cold climates.

A: NEOPROVER is a methacrylate copolymer. It is a type of PMA (polymethacrylate), a polymer of methacrylate esters.

A: In addition to the methacrylate copolymer type, the EVA type is well known. For BDF, the PMA type offers superior flow enhancement performance compared to the EVA type.

A: When BDF crystallizes, CFI prevents the crystals from elongating, thereby improving low-temperature flowability. NEOPROVER functions as a winterizing agent, ensuring smooth flow and preventing filter clogging. It can also be referred to as an anti-gel additive for BDF.

A: Not all FAMEs have poor low-temperature flowability. However, FAMEs made from raw materials with high amounts of saturated fatty acids (especially long-chain fatty acids) have high crystallization temperatures, leading to poor low-temperature flowability. Crystals that form at low temperatures can also clog filters.

A: We have developed a CFI suitable for BDF based on our extensive experience in developing additives for lubricating oils. NEOPROVER is designed for FAME made from used cooking oil, which is a mixture of various bio-based oils, making it effective for a wide range of FAMEs.