Anionic Surfactant for Cosmetics with Excellent Foaming Properties “BEAULIGHT® SHAA”

What’s great about anionic surfactant for cosmetics “BEAULIGHT® SHAA”

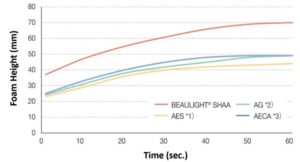

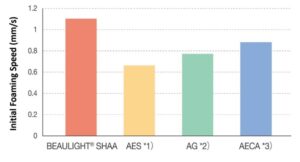

1. Foamability

”BEAULIGHT® SHAA” has a high foaming speed and forms a fine lather.

2. Hypoallergenic

As a hypoallergenic ingredient, it is suitable as a base material for shampoos, body soaps, etc.

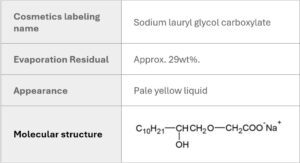

Ingredient Information

“BEAULIGHT® SHAA” Performance

Foaming speed

Using “BEAULIGHT® SHAA” as a base, a washing solution with superior foam height and initial foaming speed compared to AES (sodium laureth sulfate), AG (sodium cocoyl glutamate), and AECA (sodium laureth-4-carboxylate) can be obtained. Fig. Bubble Height

Fig. Bubble Height

Fig. Comparison of initial foaming speed

Test method

Dynamic Foam Analyzer DFA100 (KRUSS), Surfactant concentration: 0.5 mass% (active ingredient)

Test solution

*1 AES: Sodium laureth sulfate, “SANDET EN” manufactured by KRUSS

*2 AG: Sodium cocoyl glutamate, other company’s product

*3 AECA: Sodium laureth-4-carboxylate, our “BEAULIGHT®LCA-25N”

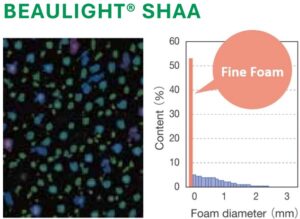

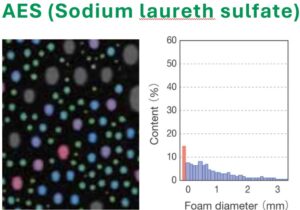

Photographs of bubbles and bubble diameter distribution after 5 seconds of stopping agitation

When “BEAULIGHT® SHAA” is used as a base material, it produces a finer foam compared to AES (sodium laureth sulfate).

Fig. Image of bubbles and bubble diameter

(BEAULIGHT SHAA)

Fig. Images of bubbles and bubble diameter

(AES: Sodium laureth sulfate *1)

Test method

Dynamic Foam Analyzer DFA100 (KRUSS), Surfactant concentration: 0.5 mass% (active ingredient)

Test solution

*1 AES: Sodium laureth sulfate, “SANDET EN” manufactured by our company

Application data

Example of formulation 1: Cleansing shampoo

| Group | Name of cosmetic ingredient labeling | Product name | Amount (wt%) |

|---|---|---|---|

| A | Water | 45.25 | |

| Citric acid | 0.15 | ||

| Cocamidopropyl betaine | LEBON 2000HG | 15 | |

| Sodium laureth-4-carboxylate | BEAULIGHT LCA-25N | 32 | |

| B | PEG-190 distearate | EMULMIN 862 | 0.5 |

| PEG-1 lauryl glycol | NEWPOL DDE-10 | 1 | |

| Sodium lauryl glycol carboxylate | BEAULIGHT® SHAA | 5 | |

| C | Phenoxyethanol | NEWPOL EFP | 0.5 |

| fragrance | 0.6 | ||

| Total | 100.0 | ||

Formulation Example 2: Sulfate-free high foaming shampoo

| Group | Name of cosmetic ingredient labeling | Product name | Amount (wt%) |

|---|---|---|---|

| A | water | 18.45 | |

| sodium benzoate | 0.3 | ||

| B | Polyquaternium-10 | 0.5 | |

| water | 25 | ||

| C | Cocamidopropyl betaine | LEBON HC-30W | 10 |

| Laureth-4-sodium carboxylate | BEAULIGHT LCA-25N | 35 | |

| Lauryl glycol sodium carboxylate | BEAULIGHT SHAA | 5 | |

| D | Polyquaternium-47 | 0.7 | |

| water | 1.4 | ||

| E | Cocamide DEA | PROFANEXTRA 24 | 3 |

| phenoxyethanol | NEWPOL EFP | 0.5 | |

| F | citric acid | 0.15 | |

| Total | 100 | ||

Compounding method

-

A: Dissolve uniformly at room temperature.

-

B: After stirring and dispersing at room temperature, heat to 70-75°C to dissolve uniformly, and then feed into A at room temperature to mix uniformly.

-

Dissolve C uniformly in the A+B mixture at room temperature.

-

While stirring the mixture of A+B+C at room temperature, feed in D and dissolve uniformly. Put E into the mixture of A+B+C+D and stir uniformly.

-

F is added to the mixture of A+B+C+D+E and the pH is adjusted to 5.5-6.0.

-

After stirring uniformly, cool and deaerate.

Click here for CITE JAPAN 2023 “BEAULIGHT® SHAA” page

Questions Asked About BEAULIGHT® SHAA and Other FAQs

A: BEAULIGHT® SHAA is a high-performance anionic surfactant that delivers high foaming, fine foam, and rich lather while maintaining mild cleansing and hypoallergenic properties. It’s an ideal sulfate alternative for use in a wide range of sensitive skin products.

A: BEAULIGHT® SHAA is widely used in shampoos, body wash, facial cleansers, hand soaps, and even baby wash products due to its mildness and high compatibility with other ingredients. It also works well in bar soap as transparent soap, shaving foam, and bubble bath formulations.

A: Yes. Its excellent foam retention and gentle properties make it perfect for cleansing gel, cleansing balm, and micellar water products, offering a luxurious and non-stripping cleansing experience.

A: Absolutely. It shows high compatibility with various surfactants, including as a replacement or complement to sodium laureth sulfate, allowing you to formulate effective sulfate-free systems.

Related Information

Related Products

Cosmetic raw materials |

Links to Sanyo Chemical’s corporate site |

Please feel free to contact us for:

・Sample requests

・Pricing requests

・TDS/SDS inquiries

・Any other technical/commercial questions

*Please note the Minimum Order Quantity of this product is 4MT/once

This page has been prepared solely for information purposes.

Sanyo Chemical America Inc. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist.