Advanced Polyethylene Compound for Rotomolding

Advanced Polyethylene Micropellets for Roto-molding

Key Advantages

Anti-Static Properties

Ensure a safe, static-free environment.

High ESCR Performance

Over 2000 hours in 10% Igepal testing, excellent longevity of parts.

Excellent Powder Flow

Superior flowability enables finer details in the fine design mold, enhancing aesthetic quality in rotomolding.

Customizable Compound

Tailor-made composition and color adjustment.

Applications

Industrial Tank

Prevent Dust Explosions and Ensure ESD Protection with Superior Anti-Static Performance.

Playground Equipment

Enjoy Playtime with Enhanced Anti-Static Comfort.

Agricultural Storage

High ESCR (>500 hours in 10% Igepal) ensures long-lasting durability and resistance to environmental stress for agricultural tanks.

Key Properties

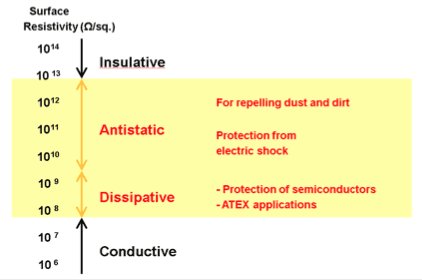

Antistatic Functions

Product Features:

- Compounds can be tailored to offer resistance between 10E+8 and 10E+13 Ω/sq.

- Anti-static properties are permanent.

- Anti-static performance remains effective even after wiping the surface with water.

- Effective anti-static properties even in low-humidity environments.

Questions Asked About Antistatic Micro Pellets and Other FAQs

A: Our antistatic PE micro pellets are designed for a wide range of applications in everyday life, including playground equipment, storage of powdered materials, and industrial tanks. They enhance the durability and longevity of products, making them ideal for both commercial and recreational uses. Their robust nature ensures that items made with these pellets are durable and long-lasting.

A: Micro pellets are distinct from powders. They possess a uniform shape and a precise particle size distribution, which enhances their flowability. This improved flowability is crucial for the acurate design and manufacture of detailed parts. Additionally, micro pellets do not contain excessively fine particles, enhancing the safety of the work environment. Their uniformity and size precision also offer significant advantages in the rotomolding market, allowing for consistent quality and efficiency in production processes.

A: LLDPE and HDPE are available. Our micro pelletizing technique is suitable for any other polymers. Please contact us if you need any other base resins.

A: The antistatic function of our micro pellets is permanent, even if their surfaces are polished with a wet towel. This enduring property ensures consistent performance throughout the lifetime of the product.

A: During molding, a conductive network forms on the surface of the resin, which prevents the resin from charging and quickly disperses any static charges.

A: Yes, it can. Feel free to ask us about your objectives.

・Looking forward to your molding trial offer.

・For sample inquiries, please reach out to us.