ACLUBE products provide the necessary viscosity stability required over the wide temperature range experienced in applications from Engine Oil, Transmission Fluid, Hydraulic fluid, and other demanding applications where lubricants provide protection to critical moving parts. We offer a wide range of viscosity index improvers and pour point depressants for lubricating oils under the trade name of ACLUBE as follows (Table1, 2).

ACLUBE Viscosity Index Improvers (VII) and Pour Point Depressants (PPD)

Table 1 Viscosity Index Improver

| Product Name | Property | Optimal Application | |||

| Appearance at 40 °C | Kinematic Viscosity at 100 °C mm2/s | Driveline, Gear oil, EV fluid | Hydraulic fluid | Engine oil | |

| ACLUBE V-1001 | Pale yellow liquid | 360 | ✔ | ✔ | |

| ACLUBE V-1010 | Straw-colored liquid | 590 | ✔ | ✔ | |

| ACLUBE V-1060 | Pale yellow liquid | 630 | ✔ | ✔ | |

| ACLUBE V-1100 | Straw-colored liquid | 490 | ✔ | ✔ | |

| ACLUBE V-2041 | Straw-colored liquid | 850 | ✔ | ✔ | |

| ACLUBE V-2000 | Straw-colored liquid | 640 | ✔ | ✔ | |

| ACLUBE V-3020 | Straw-colored liquid | 720 | ✔ | ✔ | |

| ACLUBE V-3040 | Straw-colored liquid | 1,600 | ✔ | ✔ | |

| ACLUBE V-3060 | Pale yellow liquid | 400 | ✔ | ✔ | |

| ACLUBE V-4020 | Pale straw-colored liquid | 530 | ✔ | ✔ | |

| ACLUBE V-4000 | Straw-colored liquid | 830 | ✔ | ✔ | |

| ACLUBE V-D4000 | Straw-colored liquid | 1200 | ✔ | ✔ | ✔ |

| ACLUBE V-4130 | Straw-colored liquid | 850 | ✔ | ✔ | ✔ |

| ACLUBE V-4160 | Pale yellow liquid | 300 | ✔ | ✔ | |

| ACLUBE V-5000 | Pale straw-colored liquid | 1,400 | ✔ | ✔ | |

| ACLUBE V-5040 | Straw-colored liquid | 1,000 | ✔ | ✔ | |

| ACLUBE V-5130 | Yellow liquid | 365 | ✔ | ||

| ACLUBE V-6010 | Pale yellow liquid | 1,200 | ✔ | ||

| ACLUBE V-6020 | Pale yellow liquid | 390 | ✔ | ||

| ACLUBE V-7030 | Pale yellow liquid | 1,200 | ✔ | ||

Table 2 Pour Point Depressant

| Product Name | Property | Optimal Application | |||

| Appearance at 40 °C | Kinematic Viscosity at 100 °C mm2/s | Driveline, Gear oil, EV fluid | Hydraulic fluid | Engine | |

| ACLUBE P-2090 | Straw-colored liquid | 300 | ✔ | ✔ | ✔ |

| ACLUBE P-2100 | Pale straw-colored liquid | 380 | ✔ | ✔ | ✔ |

| ACLUBE P-2320 | Straw-colored liquid | 240 | ✔ | ✔ | ✔ |

ACLUBE VISCOSITY CONTROLLING AGENT

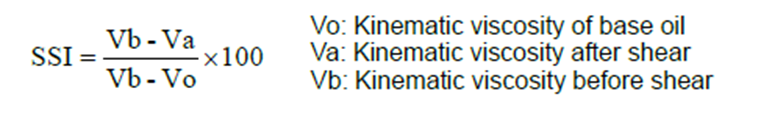

Our high-quality Viscosity Index Improver (VII) provides Improvement of a lubricant’s viscometrical property. Our unique monomer and proprietary monomer blends technology achieve excellent VI with excellent Shear stability (Table 3).

PPD products are suitable for Gr1-3 oil. Our R&D team can support your determination. We are also now focused on lubricant for Electric vehicles.

- High VI with good Shear stability

- VII and PPD for automotive lubricating oil (Driveline, Engine, Gear), Hydraulic fluid, shock absorber and etc.

Table 3 Performance of Viscosity Index Improver

| Product Name | Performance* | Feature | |||

| Kinematic Viscosity* mm2/s | Viscosity Index | SSI** % | |||

| 100℃ | 40℃ | 100℃ | |||

| ACLUBE V-1001 | 5.35 | 23.8 | 170 | 1.5 | Shear stability |

| ACLUBE V-1010 | 6.01 | 27.5 | 174 | 3.4 | |

| ACLUBE V-2041 | 7.02 | 30.9 | 200 | 14.3 | |

| ACLUBE V-2000 | 7.33 | 32.8 | 199 | 18.2 | |

| ACLUBE V-3020 | 8.49 | 37 | 218 | 28.7 | |

| ACLUBE V-4020 | 8.59 | 35.6 | 232 | 48.1 | Thickening property |

| ACLUBE V-4000 | 8.91 | 34.9 | 251 | 59.5 | |

| ACLUBE V-D4000 | 11.9 | 46.6 | 261 | 75.2 | |

| ACLUBE V-5000 | 9.79 | 37.23 | 264 | 63 | |

| ACLUBE V-5040 | 10.6 | 37.6 | 287 | 79.8 | |

* A mixture of the following base oil and a viscosity index improver (the ratio = 90:10) was evaluated.

Base oil properties: kinematic viscosity (100 °C); 4.31 mm2/s, kinematic viscosity (40°C); 20.3 mm2/s, Viscosity index: 121

The viscosity change with temperature is smaller as the viscosity index value heightens.

** Measured according to JASO M347-95 (sonic).

The shear stability is better as SSI lowers

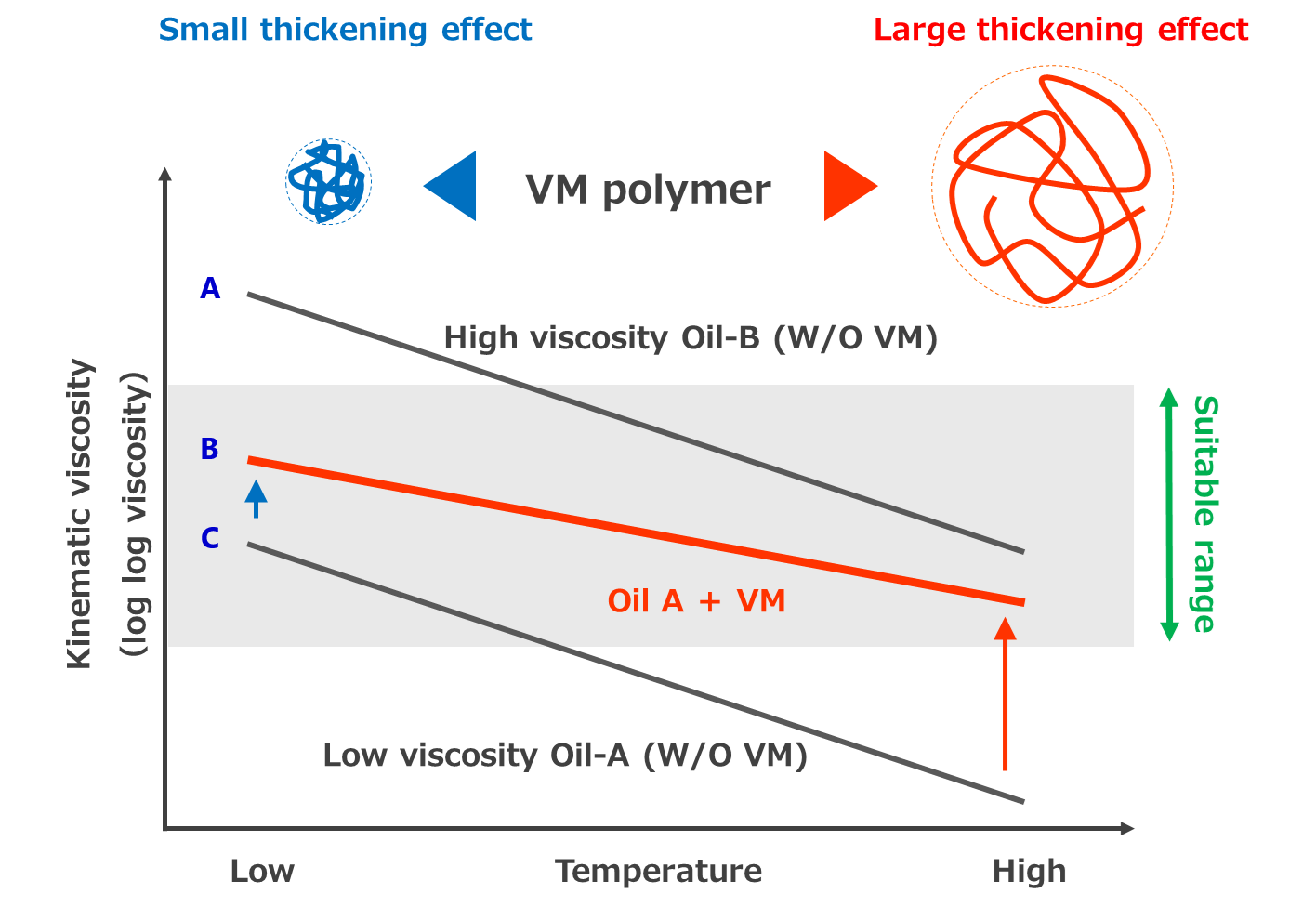

Mechanism of Viscosity Index Improver (VII)

Figure 1 shows a schematic diagram of the dissolution state of VII and the viscosity behavior of lubricating oil.

When VII is not added [A, C in Figure 1], the viscosity changes significantly with temperature, so the viscosity of low-viscosity base oils falls outside the proper range at high temperatures and that of high-viscosity base oils at low temperatures. By adding VII to low-viscosity base oils, viscosity can be maintained in the proper range over a wide temperature range from low to high temperatures [ B in Figure 1].

This is because the solubility of VII in lubricating oil changes depending on temperature, and at high temperatures, the molecular chains of VII are extended and broadened, which significantly increases the viscosity of the lubricating oil, while at low temperatures, the molecular chains of VII are contracted and become small and rounded, which has a smaller effect on increasing the viscosity of the lubricating oil.

ACLUBE POUR POINT DEPRESSANT

Lubricating oils obtained by adding ACLUBE products to base oils have excellent fluidity even at temperatures below freezing point (Table 4).

Table 4 Features of Pour Point Depressant

| Product Name | Feature |

| ACLUBE P-2090 | Suitable for the base oil (classified as groupⅢ) containing wax which is separated at low - high temperatures. |

| ACLUBE P-2100 | Suitable for base oil containing wax which is separated at high temperatures. |

| ACLUBE P-2320 |

Questions Asked About ACLUBE and Other FAQs

A: The Viscosity Index (VI) is a dimensionless number that indicates how much a lubricant’s viscosity changes with temperature; a higher VI means the viscosity remains more stable across temperature fluctuations, ensuring better performance in a wide temperature range.

A: Viscosity Index Improvers (VIIs) are essential for maintaining stable lubricant viscosity across temperature variations, ensuring optimal lubrication, reducing wear, improving fuel efficiency, enhancing performance in extreme conditions, and preserving viscosity as a critical parameter for lubricity.

A: The Pour Point is the lowest temperature at which a lubricant or oil remains fluid and can still pour under specified conditions, indicating its low-temperature flowability and usability in cold environments.

A: Pour Point Depressants (PPDs) are essential because they prevent wax crystallization in lubricants at low temperatures, improving fluidity, ensuring reliable operation in cold environments, reducing startup wear in engines and hydraulic systems, and enhancing overall lubricant performance in winter conditions.

A: ACLUBE is a methacrylate copolymer, classified as a PMA (polymethacrylate)—a polymer made from methacrylate esters. Polymethacrylates (PMAs) are premium Viscosity Index Improvers known for their excellent viscosity stability, superior low-temperature performance, strong shear resistance, and high thermal durability. While PMAs offer superior performance, they require careful formulation for optimal compatibility and come at a higher cost compared to other VIIs.

A: Viscosity Index Improvers (VIIs) are classified into the following types based on their polymer structure and performance characteristics:

1. Polymethacrylates (PMAs) – Used in engine oils, automatic transmission fluids (ATFs), gear oils, hydraulic fluids, and aviation lubricants due to their excellent viscosity control, shear stability, and pour point depression properties.

2. Olefin Copolymers (OCPs) – Common in engine oils and industrial lubricants, offering good shear stability and cost-effectiveness.

3. Hydrogenated Styrene-Diene Copolymers – Used in high-performance lubricants, providing excellent viscosity retention and thermal stability.

4. Polyisobutylenes (PIBs) – Found in industrial and marine applications, offering thickening properties and resistance to shear degradation.

5. Ethylene-Propylene Copolymers (EPCs) – Used in multi-grade engine oils and transmission fluids, providing good viscosity retention and durability.

A: Pour Point Depressants (PPDs) are classified based on their chemical composition and effectiveness in preventing wax crystallization in lubricants. The main types include:

1. Polymethacrylates (PMAs) – Used in engine oils, gear oils, hydraulic fluids, and transmission fluids, offering excellent low-temperature flow improvement and compatibility with VIIs.

2. Ethylene-Vinyl Acetate (EVA) Copolymers – Common in diesel and heavy fuel oils, preventing wax precipitation by modifying crystal structure.

3. Alkylated Naphthalene-Based PPDs – Effective in fuel oils and lubricants, reducing wax formation and improving low-temperature performance.

4. Polyalphaolefin (PAO)-Compatible PPDs – Designed for synthetic and high-performance lubricants, ensuring pour point reduction without affecting oil stability.

5. Succinimide-Based PPDs – Used in industrial lubricants and specialty fluids, providing pour point suppression and deposit control.

Each type of PPD is selected based on the oil formulation, application, and temperature conditions to optimize low-temperature performance.

A: To choose the right ACLUBE Viscosity Index Improver (VII) or Pour Point Depressant (PPD), consider factors such as application type (engine oils, ATFs, hydraulic fluids, gear oils, or EV fluids), viscosity requirements, shear stability, and pour point needs. If you need further assistance, please contact us using the form below.